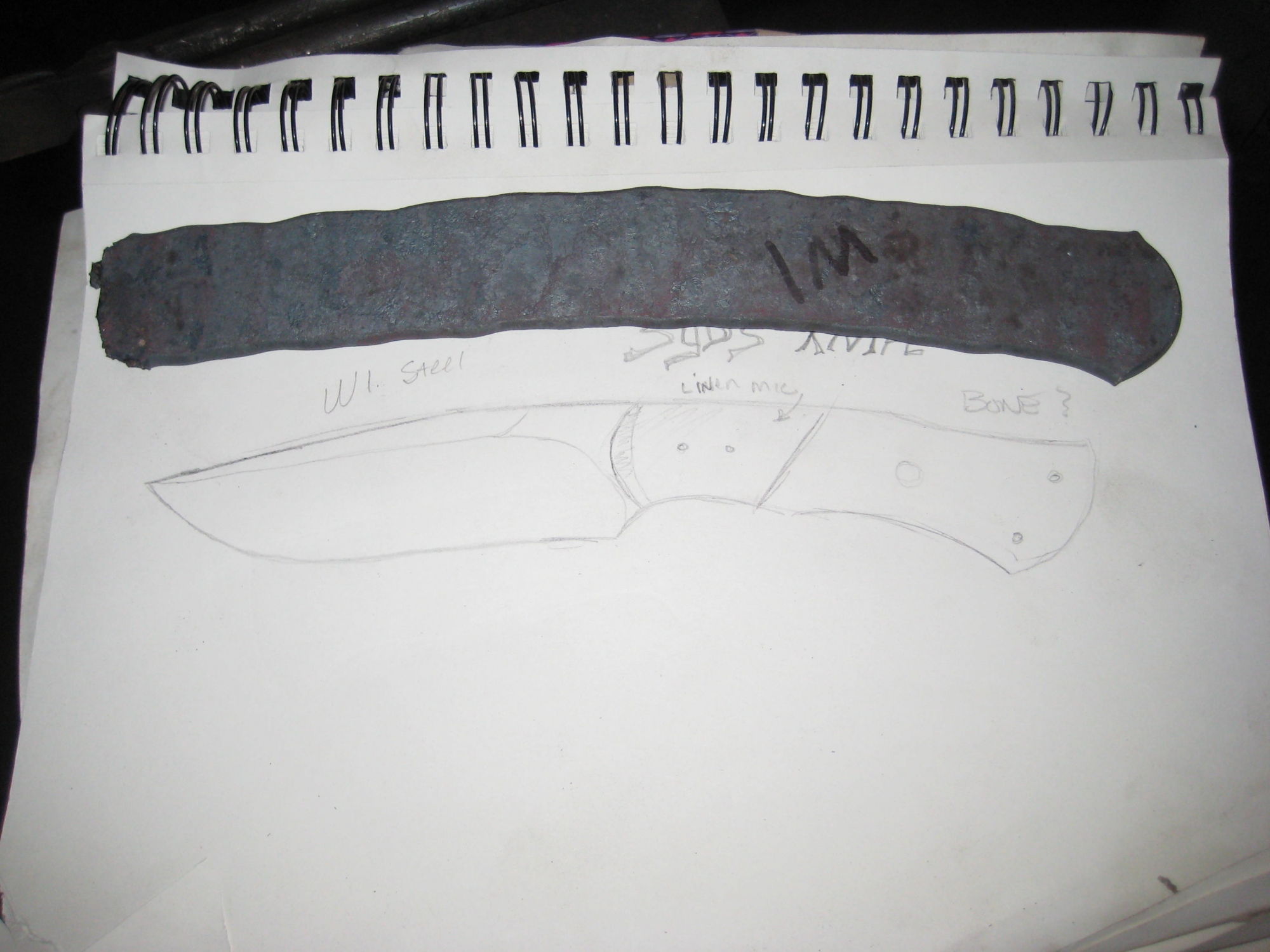

Here is the drawing that I did. I will try to make the knife as close to this as possible, however, I sometimes make slight alterations along the way.

This is the bar that I started with. It is 1" diameter W1 drill rod. I cut a few sections of it to make several pieces, just in case I screw one up.

Here it is ready to be welded on a piece of rebar. I do this so I can draw it out to the dimensions I want without burning my hands!

I am not a welder, so bear with me. I just need it to hold on during the forging.

Here is my forging setup. I have a vertical forge I made, and press I bought with a friend of mine. (It is all in his shop, literally across the street from me.)

Here it is all up and running. The forge will get around 2300 degrees, enough for forge welding steel.

I love this press. It pushes at 24 tons and can turn that 1" roundbar into a pancake. I use flat dies to press it down to about 5/8", then drawing dies to draw it out to stretch the steel.

Here it is on the floor cooling.

In this shot, the forge is actually off and cooling. I told you it gets hot in there.

Here is the afternoon's work. Two of these are W1 and two are W2. Not much difference except that W2 has a little more vanadium. There could be more, but I am not a metallurgist.

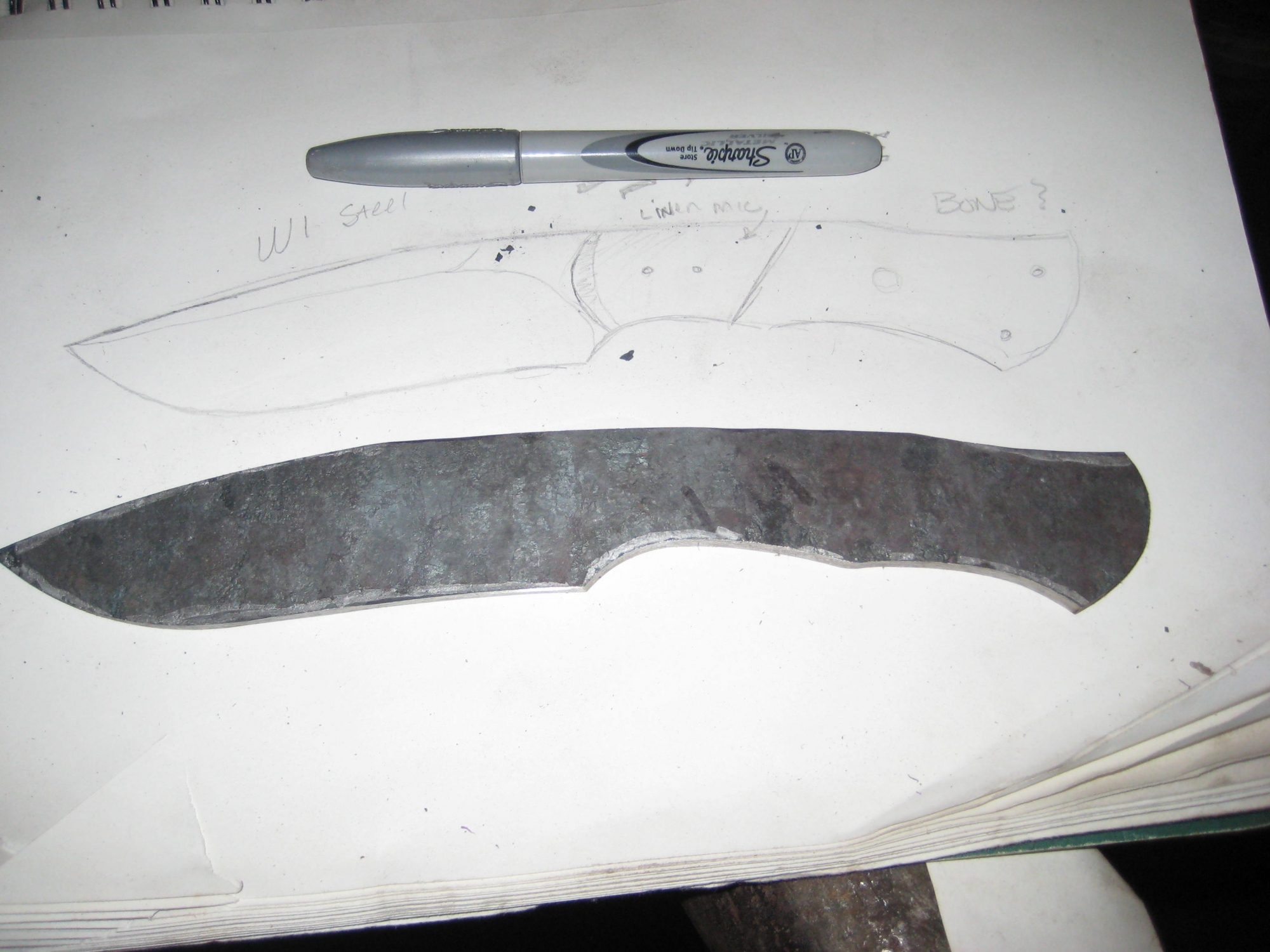

Here is the steel blank next to the drawing. Pretty close and I think it will work nicely.

Ok, Here is where forging purists would say I am cheating, and maybe I am. I hate trying to forge the tip in, so I cut it in on my bandsaw. I figured that while I was at it, I would also cut the handle out. I will forge the bevels in later, but this saves me a lot of time and only wastes a little steel.

Here it is next to the drawing. As you can see there are some differences, I may change it a bit, or I may leave it as it is. Next step, forging.

Here is my forging setup. My shop tends to be a bit cluttered, but I have the forge running and my anvil ready. My photographer will make an appearance later. The next few shots will be all of me forging, some with flash, and some without. The shots without flash are a little blurrier, but they show the actual color of the steel as I bring it out of the forge.

My photographer giggled at this one because she said it looked like I was hitting myself in the nose with my hammer.

I actually really like this shot. My photographer rocks!

Here is my photographer. She is cute,and she works for candy!