Here are all of the pins installed

The knife has been rough shaped on the grinder, and I am touching it up with a cabinet maker's file. It works great and is easier to get things accurate than it is with a belt that is hogging off material at a very fast pace.

The handle has been hand sanded to 600 grit at this point. I buff the wood and micarta to give it a nice glossy sheen. My hands are pretty dusty at this point

Here it is all clean and buffed. It feels great in the hand. I hope it makes it's new owner happy.

Here I am making the pattern for the sheath. It never made a lot of sense to me to make an expensive knife and not make a decent place to put it. I actually enjoy making sheaths now that I have my new sewing machine.

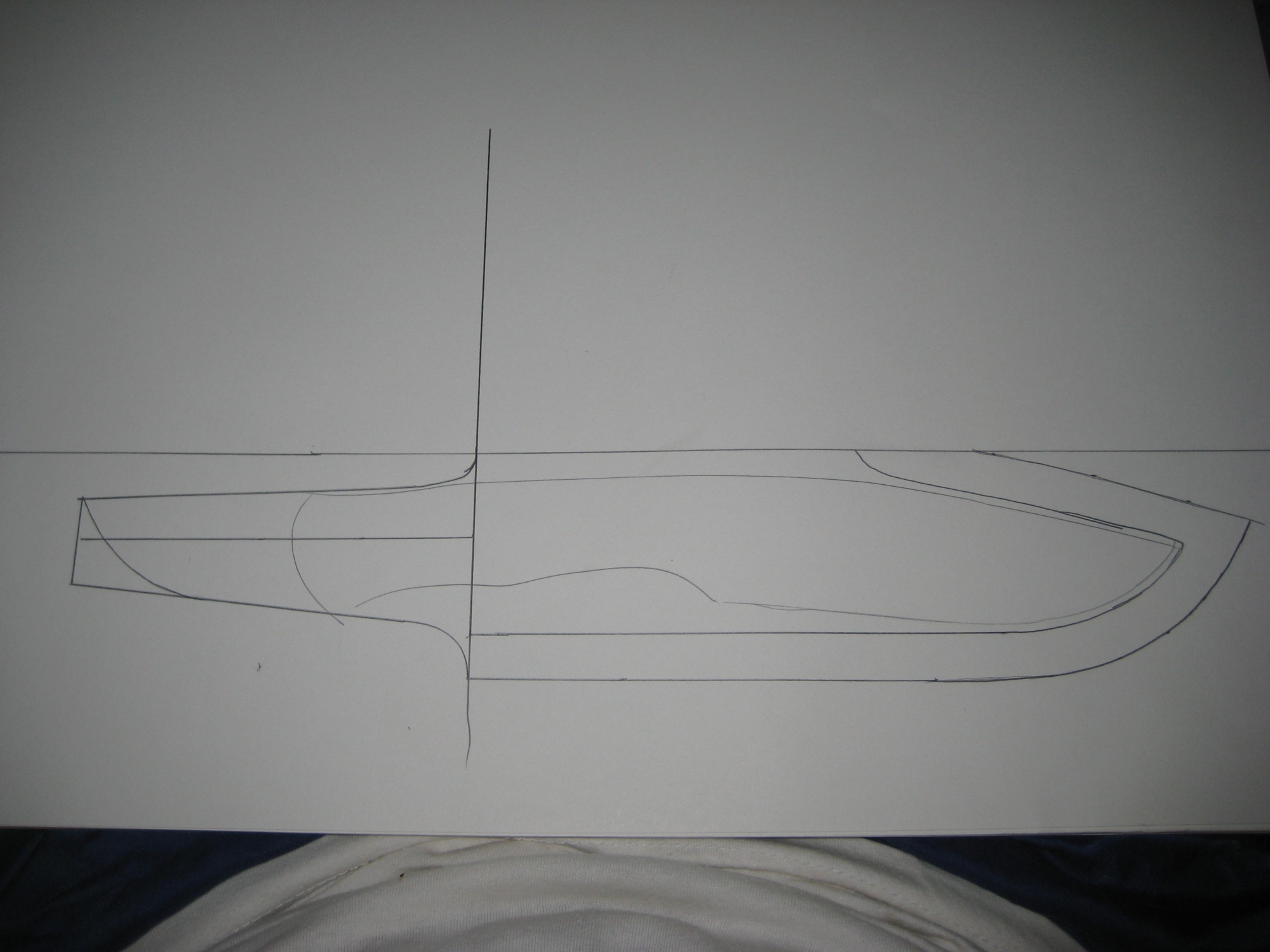

This is the pattern I made from this knife. I got the information from Paul Long on his DVD. He gives great information and is a very nice man in general. He gave his phone number on his DVD, and I called him with some questions. Guess what, he actually answered and gave me really great advice.

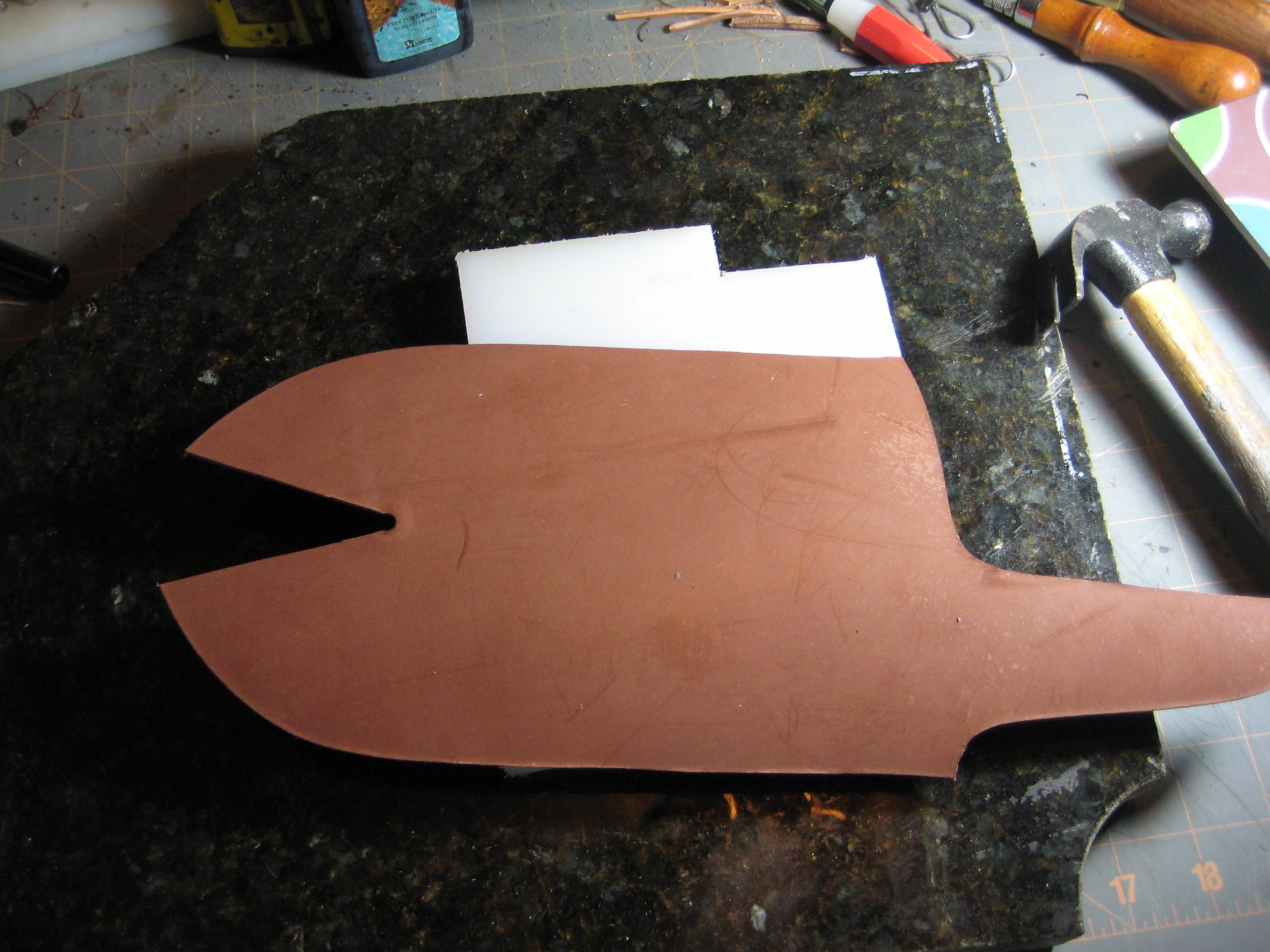

Traced on the leather.

Cut out

Border is gouged at this point.

I started a basket weave pattern, using my small basket weave stamp. I have a larger one which makes the entire process go about 4 times faster, but I like the look of the smaller one better. That thing is really tiny, and this process takes forever.

Half done.

All done with the filler. This process probably took me about 40 minutes, maybe a little less.

This is where I am for tonight. I did a border around the edge of the basketweave, and made some accent lines around the opening of the knife. They are all small things, but make a huge difference in the final result.